Premium Quality for Your Success

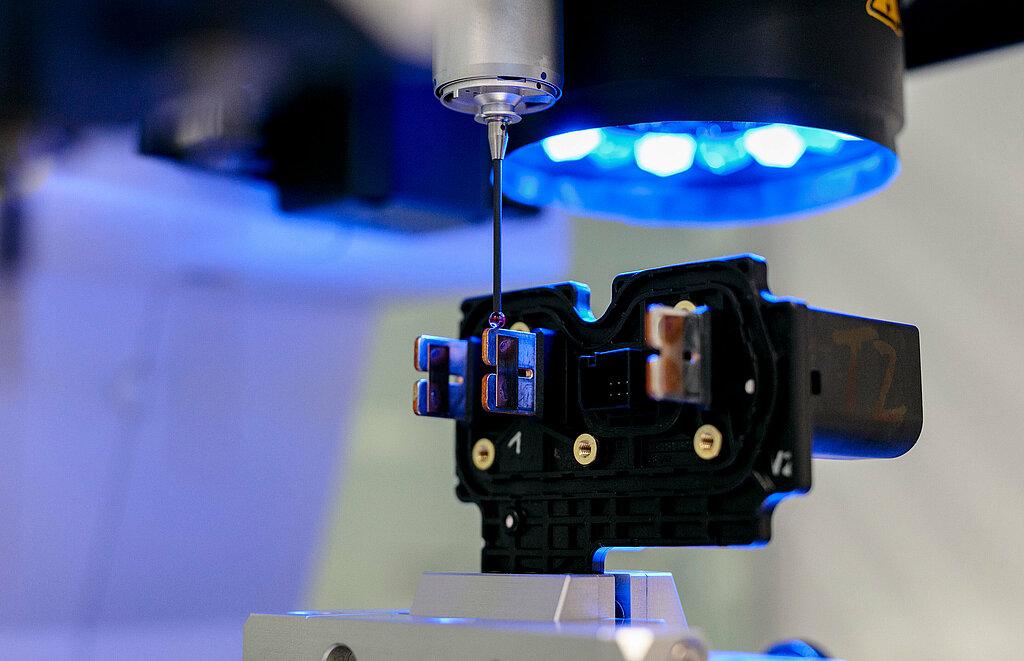

We set ourselves the highest quality standards. To ensure the maximum performance of our products we use simulations and laboratory tests.

Quality Is Our Top Priority

Our materials, procedures and processes are continuously evaluated and adapted to latest standards. Furthermore, certified quality is a matter of course at all our locations worldwide. We are certified to the standards IATF 16949, ISO 14001, ISO 45001 and ISO 9001 and the Authorised Economic Operator (AEO) guidelines.

The satisfaction of our customers is equally important to us: More than 500 employees work for our certified quality management worldwide. We are constantly investing in the expansion of technology, resources and know-how.

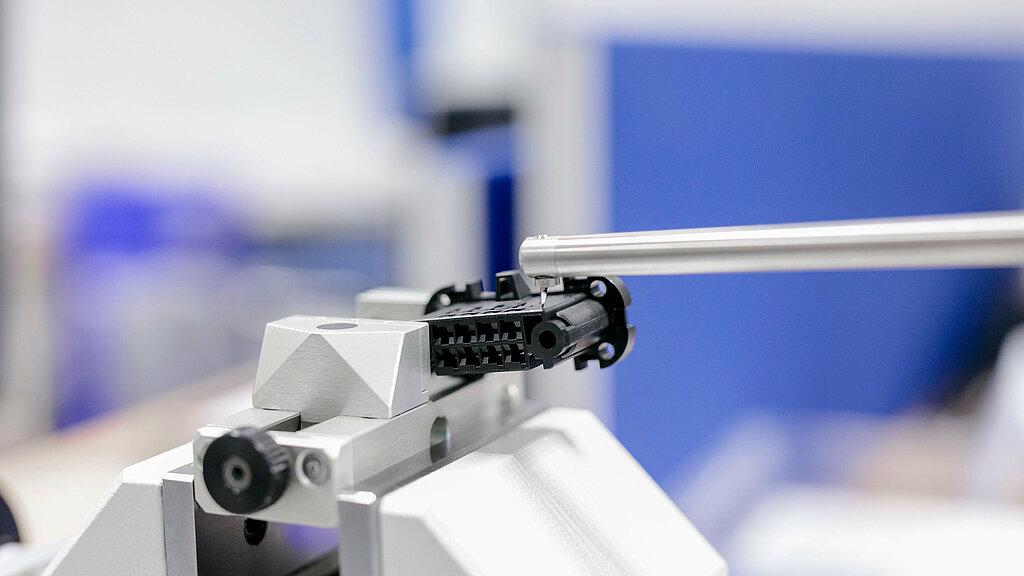

Quality Check at Every Step

An integral part of our development philosophy is the seamless testing and qualification of all components – from the design and construction phase to series-production readiness. We apply state-of-the-art simulations and laboratory tests all the time. In this way, we guarantee the maximum performance of our products throughout their entire life cycle.

Matthias Bell

Matthias Bell, Quality Director

Custom Testing and Analysis Services

Hirschmann Automotive offers a comprehensive range of services to external customers, fully aligned with the DIN EN ISO/IEC 17025 standard to ensure the highest levels of quality and reliability. Detailed quotations are available upon request to support quality assurance needs.

The New Technical Cleanliness Area in Târgu Mureș

New Technical Cleaniness Area | in Târgu Mureș

Through Heart and Hand to Premium Solutions

The automotive industry demands a high level of product quality. Therefore, employees of the quality department are already involved in inquiries for new projects. In this way, the fulfillment of customer requirements can be ensured at an early stage. At the same time, Hirschmann Automotive sets great value on the sound training of its quality specialists. This is how we meet our customers on a level playing field.